(22 - 28 Sept. 2014)

The ice camp

Construction of the FRAM-2014/15 ice camp was completed on Saturday (see picture). The direction of the ice drift relative to our target area have allowed us to invest about 2 weeks of full attention to obtain a net 128 square meter area of protected working conditions at a reasonable price. All the building materials are locally derived, except for tarps from sail maker Iversen, Bergen, some 2" x 4" lumber and a few sheets of plywood.

We had to contend with establishing the camp on first year ice. The bearing capacity of a visco-elastic ice sheet is primarily dependent on temperature and ice thickness. Present temperatures are still high and the 1.2 m thick ice is relatively soft. The ice camp is about 200 meter from the nearest lead and the ice and snow walls represent an estimated 30 ton load over a 14 m x 14 m area. The weight of the hovercraft and equipment represent another 10 tons. From published load capacity curves it appears we are at the limit of safe loading. Changes in relative water levels as the construction progressed, suggests a down-bending of the order of 10% of the ice thickness.

Ice drift and camp life

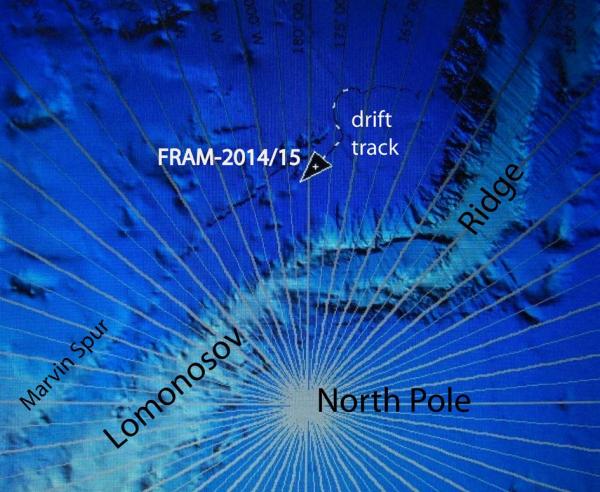

The camp drifted 38 nautical miles (70 km) during the last week, generally towards the north and partly perpendicular to the Lomonosov Ridge (see picture). The ice moves at a speed of about 2% of the wind speed as observed by Nansen. Our motion during the week has largely been determined by a deep low pressure which moved through the Fram Strait and was centered at the North Pole on Tuesday 23 September and our position the next day. Wind speeds were 30-33 knots during Wednesday after noon , coming down to 20 knots through Thursday. Drifting snow come with high winds. Snow storms have their own charm, their message being; … "Nature Rules"! Unfortunately they tend to turn your attention away from planned useful work to upkeep of the camp facilities. To our great relief, the 126 square meter tarp over the ice hangar held up really well in winds over 30 knots . However, the winter is long and in hindsight, cross-going tie-down straps should have been attached to the canvas for every meter to properly secure the large tarp. Protection from the wind chill is considered essential, and we also have an independent back-up solution for covering the hovercraft during the winter. Another issue we needed to clarify was; could we run the hovercraft propeller under the tarp? The variable pitch propeller always turns with the engine and we need the engine running to get hydraulic power to the winch and to drive the compressor. This also appeared to be no problem at all.

The sun will go below the horizon on Tuesday 30 Sept. at this latitude and be back about 15 March.

No sign of animal life in any form during the week

Science

Our oceanographic equipment suspended below the ice continuously monitor ocean currents in the upper 500 meters of the water column and at points 800 and 2000 meter depth. Water depth is monitored by a 3.5 kHz echo sounder which gives a sub-bottom penetration of about 20 meter. Within 6 km radius of the camp are five autonomous buoys which also monitor water depth. On the ice, the radiation flux instruments are running, but icing is a problem for the sun time monitor and snow for the vertical IR skin temperature probe. The weather station appears robust.

On Wednesday, we started work on the seismic gear, an endeavor associated with a string of start-up, non-cold and cold related problems not overcome until the afternoon on Saturday. You need high pressure air, a working airgun and a data logging system. We first discovered that the engine mounted hydraulic pump which power the compressor as well as the winch, had sprung a seal, a problem we cannot fix here. However, a potential misfortune of this nature was foreseen and we connected a spare external belt driven pump. The compressor did not like the cold and a heated enclosure had to be built. On the first try, the pump drive belt started screaming, because the load from the viscous cold oil, was too large - we also needed to pre-heat the oil reservoir. Once we are in operation, you start the main engine every few hours and the pre-heat issue goes away. Getting the airgun going was trickier. As the air pressure was put on, the relatively new and little used Bolt PAR 0.3 litre airgun did not close, but started firing rapidly on the floor (auto-fire). We dismantled the device completely and changed every visible seal, put it together, but the result was still auto firing. At this point we consulted with external marine seismic industry expertise, all suggesting the problem was the solenoid valve which controls the air supply to the piston. However, Einar Gjestrum (retired), who last worked with Bolt airguns over 30 years ago was more specific; "It is an o-ring which has part number 640", he said, and that was correct! We also had to consult with our institutional expertise on communications port allocation issues related to the gun control box to get the data logging system work right.

The airgun is giving a penetration of about 2 km below the seabed. Seismic lines from icebreaker surveys suggest this is the maximum sediment thickness in this part of Makarov Basin. During the short time we have been operational, the ice drift has taken us parallel to the trend which is assumed to be a large fracture zone along the foot of slope of Lomonosov Ridge. The geologically significant issue is whether or not we can see any sign of deformation in the deepest sediments.

All is well.

Yngve Kristoffersen & Audun Tholfsen

Daily reports

Monday 22 September.

Position: 87 25.3' N, 171 49' E, temperature - 7 C, air pressure 1007 hPa, wind 7 knots from WSW. Worked all day securing the tarp. Checked radiation flux instruments twice and removed ice.

Tuesday 23 September.

Position: 87 25.9' N, 173 44' E, temperature - 10 C, air pressure 1004 hPa, wind 15 knots from SE. Ice drift 0.4 knots towards NE. Finished the last wall of the bath room and with that all ice hall construction work is finished. Drifting snow and 15-20 knot winds all day. Checked Met.no radiation flux instruments for ice twice during the day.

Wednesday 24 September.

Position: 87 31.5' N, 175 26' E, temperature - 8 C, air pressure 990 hPa, wind22 knots from E. Drifting snow. Ice drift 0.4 knots towards NNE. Wind speeds 30-33 knots in the afternoon and evening. Started preparations for seismic reflection measurements. The compressor needs to be pre-heated and an insulated enclosure had to be made. Worked on getting the data logging system up and had support from Bergen via Iridium to tackle computer communications port allocation issues. Audun worked all day securing the tarp over the ice hangar.

Thursday 25 September.

Position: 87 43.9' N, 174 43' E, temperature - 13 C, air pressure 1003 hPa, wind 20 knots from NE. Ice drift 0.3 knots towards NW.

Data logging system running. Discovered hydraulic pump for driving the compressor and winch had blow a seal and hydraulic oil been routed into the main engine. Prepared spare belt driven external pump. When pressure was put on the Bolt PAR airgun before putting in the water, the gun went into auto-fire and would not close. The gun was completely dismantled and all visible o-rings were changed. On the next try, the gun still went into auto fire.

Friday 26 September.

Position: 87 47.9' N, 173 39' E, temperature - 8 C, air pressure 1007 hPa, wind 8 knots from ENE.

Contacted old hands with long industry experience from marine seismic surveys. Most suggestions pointed to the solenoid valve which controls air flow, but Einar Gjestrum who last worked with Bolt airguns for GECO about 30 years ago was more specific. It is "O-ring; part number 640", he said, and that was really the problem. When started cold, the belt driven hydraulic

pump struggle, because of the viscosity of cold oil. This means that we have to pre-heat both the compressor and the hydraulic oil reservoir every time we need to recharge the air tanks for the airgun. It is cumbersome, but not a logistical problem. Removed ice from the radiation flux instruments. Audun put up a tarp over the store room.

Saturday 27 September.

Position: 87 50.1' N, 173 35' E, temperature - 6 C, air pressure 1006 hPa, wind 3 knots from NE. Ice drift 0.1 knots towards NE. Two centimeter of new snow on the ground. Start up of seismic reflection measurements delayed by intermittent loss of the hydrophone signal. The problem was a defect power plug. At 1640 hours, we were finally acquiring seismic data. Put the generator on styrofoam pads to reduce the acoustic noise transmitted via the ice into the water. Checked radiation flux instrumentation and removed ice from the sun time sensor and snow from the IR-sensor. Audun worked on finishing the bath room.

The ice has sunken about 20 cm relative to the water level due to the load of the camp probably augmented by regional compression during the recent days of strong wind and ice drift. In the annex for geology & geophysics, we have to recover frozen-in floor and wood frame to adjust to the new level.

Sunday 28 September.

Position: 87 51.7' N, 173 59' E, temperature - 10 C, air pressure 1006 hPa, wind 6 knots from SE. Acquiring seismic data. Penetration about 2 km below the seabed over the abyssal plain using the 0.3 litre airgun fired every 25 meter. Audun worked on the bath room.

Fram-2014/15 camp completed.

Cutting ice blocks for construction of the ice hangar at an adjacent refrozen melt water pond.

Ice drift of FRAM-2014/15 during week 4 is shown by white stippled track.